Horizon cruise terminal

About the project

The newest Southampton cruise ship terminal was named “Horizon” and officially opened in September 2021. It is the fifth terminal at the Port of Southampton, but the first one in terms of environmental friendliness: Featuring roof-mounted solar panels and the first shore-side power facility in the UK, it has been quoted as “Britain's greenest” by the media. Berthed cruise ships can turn off their engines and use the clean shore power plug-in charging instead, effectively reducing pollution.

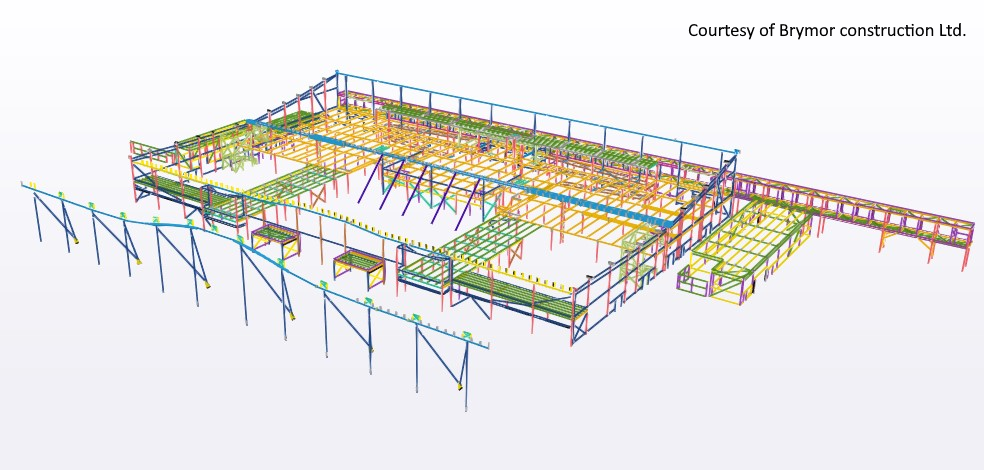

Apart from green infrastructure, the £55m terminal features an impressive entrance consisting of six steel tripods and a glulam canopy, and an air bridge for direct access to the docked ship. The internal floor area of over 100,000 square feet includes a 42,500 sq ft mezzanine floor above a 65,000 sq ft baggage handling area. Construction comprised a 700-ton steel frame structure on piled foundations that support the roof, formed of curved 1400 mm deep glulam beams at 1500 mm centers supporting a timber deck.

The building was produced by REIDsteel in cooperation with Brymor Construction Ltd and HESS Timber. REIDsteel delivered all steelwork using materials sourced from British Steel.

Engineering challenges

During the tender stage of the project, the REIDsteel company was approached by the client with an initial draft of the construction design, which was excessively heavy and therefore had high demands on the building foundations. Using IDEA StatiCa, REIDsteel engineers conducted an extensive value engineering exercise, and as a result, they were able to reduce the peak foundation reactions by a factor of 10. This obviously led to significant savings on the client’s side and won REIDsteel the contract.

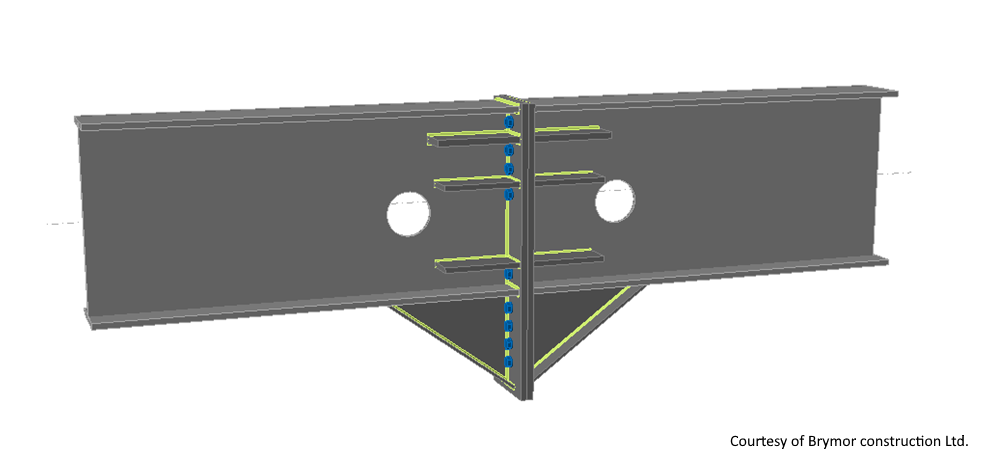

A critical part of the project for REIDsteel was the integration of connections between the glulam and the steel. These connections needed to be designed for rigidity as to withstand the erection phase without twisting, but also for flexibility in the future, as glulam—being engineered wood—tends to creep over time and needs space for movement.

Another challenge was the splice design. The splices had to provide a solid support for the weight of the roof including a potential load of snow. At the same time, aesthetical criteria set by the client had to be met in places where the splices could not have been hidden within the glulams.

Similarly, very specific requirements, both visual and functional, were applied to the tripods at the building entrance. All the challenges had to be resolved to the highest security standards without increasing costs.

Solutions and Results

All mentioned challenges could have been resolved using traditional methods and manual calculation, but on a project like the Southampton ship terminal, with hundreds of connections of different types, this would have meant months of extra work. IDEA StatiCa, on the other hand, provided the structural engineering team at REIDsteel with instant calculations of deflection, buckling, splice plates, and other crucial connections. They were able to evaluate any change in design requested by the client and choose the best solution in a very short time.

In particular, REIDsteel engineers found IDEA StatiCa helpful for checking the rigidity of the connection. This type of calculation is extremely difficult and time-consuming to do manually, and IDEA StatiCa could do it automatically and instantly.

The whole project, from design to erected construction, took less than seven months. REIDsteel engineers are confident to state that without the IDEA StatiCa software, it would have taken twice as long. They also acknowledge that IDEA StatiCa played a key role in the initial analysis for the client, which was completed with impressive results and helped REIDsteel win the contract. Overall, IDEA StatiCa helped save a significant amount of effort, time, and cost on the part of both the company and its client.

About REIDsteel

REIDsteel, or John Reid and Sons Ltd, is a structural steel firm based in Dorset, England. Founded in 1919, REIDsteel has become an expert in the design, fabrication, and erection of large industrial constructions, including but not limited to aircraft hangars, warehouse and office buildings, grandstands, and stadiums, car parks, and steel bridges. The company’s work is renowned globally for its exceptional safety and has won multiple Queen’s Awards for Enterprise in the International Trade category.

Learn what the engineer says about the project

Horizon cruise terminal gallery